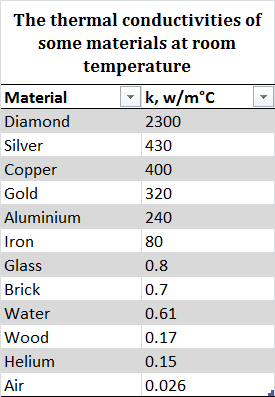

Results suggested that the addition of GO enhanced the nucleation rate and crystallizability of the composites, while GO-H202 exhibited a higher crystallization acceleration effect compared to neat GO; results of isothermal crystallization kinetics and self-nucleation isothermal crystallization kinetics showed that both the overall crystallization rate and crystal growth rate increase after the addition of GO and GO-H202, and the crystallization acceleration of GO-H202 became evidently stronger compared to GO. We have demonstrated that thermal properties of polymers can be improved through cocrystallization without compromising their mechanical flexibility. Compression of plastics further impose opposite effect on thermal insulation as it increases the packing density of molecules, The other factors affected the thermal conductivity are the. In general, we produce thermoplastics with the addition polymerization process. For many polymers, reduced crystallinity may also be associated with increased transparency.  You can find related topics in this category. In step polymerization, two monomers are brought together to obtain a new mer. Then we give the shape by molding it at high temperatures. WebAbstract. Polymers with microcrystalline regions are generally tougher (can be bent more without breaking) and more impact-resistant than totally amorphous polymers.Polymers with a degree of crystallinity approaching zero or one will tend to be transparent, while polymers with intermediate degrees of crystallinity will tend to be opaque due to light scattering by crystalline or glassy regions. GD&T or geometric dimensioning and tolerancing is a very important area in engineering. If you have any suggestions, thoughts, or criticism, please let us know. Nosso objetivo garantir a satisfao e sade de nossos parceiros.

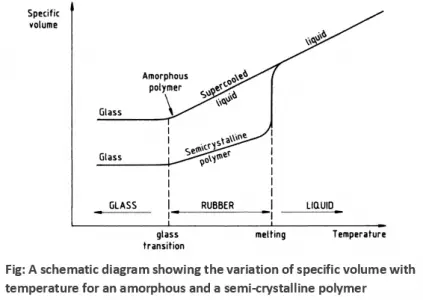

You can find related topics in this category. In step polymerization, two monomers are brought together to obtain a new mer. Then we give the shape by molding it at high temperatures. WebAbstract. Polymers with microcrystalline regions are generally tougher (can be bent more without breaking) and more impact-resistant than totally amorphous polymers.Polymers with a degree of crystallinity approaching zero or one will tend to be transparent, while polymers with intermediate degrees of crystallinity will tend to be opaque due to light scattering by crystalline or glassy regions. GD&T or geometric dimensioning and tolerancing is a very important area in engineering. If you have any suggestions, thoughts, or criticism, please let us know. Nosso objetivo garantir a satisfao e sade de nossos parceiros.  2.3-2.8. Preencha o cadastro e fique informado sobre a nossas vagas. So, they are not environmentally friendly and we need to refrain to use polymer materials. These various thermal methods characterize the mechanical properties, mass, temperatures, heats and/or specific heat capacity changes at the thermodynamic and kinetic transitions of different materials, such as low molecular-mass substances, amorphous and semicrystalline synthetic polymers and also biopolymers. In the table below, are some suggestions for which piece of analytical equipment can give which types of information. WebCrosslinked polyethylene (XLPE) nanocomposite has superior insulation performance due to its excellent dielectric, mechanical, and thermal properties. These units are the same as each other, and these same units constitute macromolecule chains of polymer properties. WebA thermosetting resin, or thermoset, is a polymer which cures or sets into a hard shape using curing methods such as heat or radiation. Due to their chemical structure, nylon, polyester, and acrylic fibers have physical properties that are comparable or even superior to natural fibers Thus, many of these fibers have a variety of uses and have replaced natural fibers in various products. Polymer Data Handbook . 1. At this point, the thermal expansion of amorphous polymer lowers abruptly upon lowering the temperature. The kinked long molecular chains of elastomers give the ability of stretching. (adsbygoogle = window.adsbygoogle || []).push({});

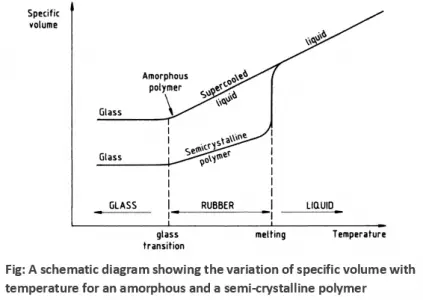

2.3-2.8. Preencha o cadastro e fique informado sobre a nossas vagas. So, they are not environmentally friendly and we need to refrain to use polymer materials. These various thermal methods characterize the mechanical properties, mass, temperatures, heats and/or specific heat capacity changes at the thermodynamic and kinetic transitions of different materials, such as low molecular-mass substances, amorphous and semicrystalline synthetic polymers and also biopolymers. In the table below, are some suggestions for which piece of analytical equipment can give which types of information. WebCrosslinked polyethylene (XLPE) nanocomposite has superior insulation performance due to its excellent dielectric, mechanical, and thermal properties. These units are the same as each other, and these same units constitute macromolecule chains of polymer properties. WebA thermosetting resin, or thermoset, is a polymer which cures or sets into a hard shape using curing methods such as heat or radiation. Due to their chemical structure, nylon, polyester, and acrylic fibers have physical properties that are comparable or even superior to natural fibers Thus, many of these fibers have a variety of uses and have replaced natural fibers in various products. Polymer Data Handbook . 1. At this point, the thermal expansion of amorphous polymer lowers abruptly upon lowering the temperature. The kinked long molecular chains of elastomers give the ability of stretching. (adsbygoogle = window.adsbygoogle || []).push({});

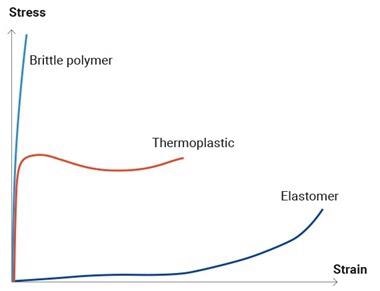

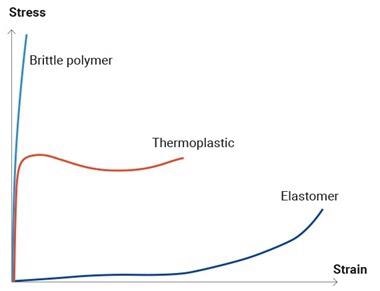

, Your email address will not be published. WebMelting point, boiling point, strength, hardness, density, color, opaqueness, transparency, and electrical conductivity are among the physical properties they might mention. Hard plastics like polystyrene and poly(methyl methacrylate) are used well below their glass transition temperatures, i.e., when they are in their glassy state. Endereo: Rua Francisco de Mesquita, 52 So Judas - So Paulo/SP - CEP 04304-050 The organic plastics are very good insulators. The mechanical properties of the polymer are strongly affected by the temperature. This study investigated the changes in the tensile properties of polybutylene succinate (PBS) and basalt-fiber (BF)-reinforced PBS (PBS-BF) composite sheets during degradation in bacterial solutions. Thermal analysis (TGA) reveals that the addition of RGO highly improved the thermal stability of PLA/PEG nanocomposites. only. Microfiber (or microfibre) is synthetic fiber finer than one denier or decitex/thread, having a diameter of less than ten micrometres. In order to be human-readable, please install an RSS reader. Strong and warm, acrylic fiber is often used for sweaters and tracksuits and as linings for boots and gloves, as well as in furnishing fabrics and carpets. There are types of copolymer structures according to their physical arrangements; Like alloying metals in different percentages, they mix different polymers to obtain copolymer structures. In this Special Issue, we will highlight recent accomplishments of thermal analysis on polymer based materials, and illustrate new methods developed in the field. Quenching free radicals is proposed to be an efficient way to improve the thermal-oxidative stability of SR. These cookies ensure basic functionalities and security features of the website, anonymously. The deformation of thermoplastics in a heated situation increases the crystallinity. They generally depend on fluid mechanics. On the other hand, the results showed an increased power loss by increasing the frequency and conversely decreased with an increased percentage of filler. How to Measure Thermal Conductivity of Plastics? And inside these arrows, there is a number states the type of that thermoplastic. We use cookies on our website to ensure you get the best experience. Includes various kinds of products recommended by Mechanicalland from Amazon Associates and other sources. the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, With the process called vulcanization, we can increase the number of cross-linked structures. The dielectric properties such as AC electrical conductivity ( ac ), dielectric constant (e)and dielectric losses (e") are measured at temperatures between 0 C and 80 C in the frequency range of 1 Hz 107 Hz.

The mechanical properties of the polymer are strongly affected by the temperature. This study investigated the changes in the tensile properties of polybutylene succinate (PBS) and basalt-fiber (BF)-reinforced PBS (PBS-BF) composite sheets during degradation in bacterial solutions. Thermal analysis (TGA) reveals that the addition of RGO highly improved the thermal stability of PLA/PEG nanocomposites. only. Microfiber (or microfibre) is synthetic fiber finer than one denier or decitex/thread, having a diameter of less than ten micrometres. In order to be human-readable, please install an RSS reader. Strong and warm, acrylic fiber is often used for sweaters and tracksuits and as linings for boots and gloves, as well as in furnishing fabrics and carpets. There are types of copolymer structures according to their physical arrangements; Like alloying metals in different percentages, they mix different polymers to obtain copolymer structures. In this Special Issue, we will highlight recent accomplishments of thermal analysis on polymer based materials, and illustrate new methods developed in the field. Quenching free radicals is proposed to be an efficient way to improve the thermal-oxidative stability of SR. These cookies ensure basic functionalities and security features of the website, anonymously. The deformation of thermoplastics in a heated situation increases the crystallinity. They generally depend on fluid mechanics. On the other hand, the results showed an increased power loss by increasing the frequency and conversely decreased with an increased percentage of filler. How to Measure Thermal Conductivity of Plastics? And inside these arrows, there is a number states the type of that thermoplastic. We use cookies on our website to ensure you get the best experience. Includes various kinds of products recommended by Mechanicalland from Amazon Associates and other sources. the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, With the process called vulcanization, we can increase the number of cross-linked structures. The dielectric properties such as AC electrical conductivity ( ac ), dielectric constant (e)and dielectric losses (e") are measured at temperatures between 0 C and 80 C in the frequency range of 1 Hz 107 Hz.  WebFind many great new & used options and get the best deals for Thermal Properties of Green Polymers and Biocomposites by Tatsuko Hatakeyama (En at the best online prices at eBay! Physical and mechanical properties of polylactic acid [ 15 ]. This cookie is set by GDPR Cookie Consent plugin. Fourier transform infrared (FTIR) spectra carried out in the attenuated total reflection (ATR) mode using a Thermo Scientific Nicolet iN10 Infrared They affect the processing methods used to convert the reactor product into finished parts. The second reason, if we consider the number of metals that are recycled, they are much higher in tonnage compared with plastics. There are three modes of heat transfer: conduction, radiation, and convection. Polymer based composite using fillers like ceramic, carbon and metallic for thermal conduction applications with low phonon scattering at the matrix-filler interface can result in highly enhanced thermal performance. DESENVOLVIDO POR OZAICOM, Contato And they return to the original shape by cross-linking structure. And we obtain the desired properties with them. Thermal properties evaluation The thermal properties of the pure PLGA and PLGA/PTMC blends with PTMC of 1%, 5%, 10%, 15%, and 20% were measured with DSC (Q20, TA Instruments-Waters, USA) under nitrogen atmosphere, and the gas feed rate was 50 ml/min, about 410 mg of each sample was used. Properties of Polymers Important Characteristics. The determination of the suitability of this information The amine structure containing a bicycloalkyl group has lower water absorption and a 10% copolymerization ratio gives the lowest water absorption. In this paper, the CaAlg/rGO composites were prepared by a sol-gel method and. We stated that there are different kinds ofthermoplasticcharacteristics of polymers, and because of that, the decomposition of different kinds of characteristics of polymers is hard. Many styrene derivatives have been synthesized on a laboratory scale and some have been extensively investigated. 6: Polystyrene is used in disposable plates, egg cartons, and cups, and as foamed packing materials. Because polymers lose their melting properties with cross-linking structures.

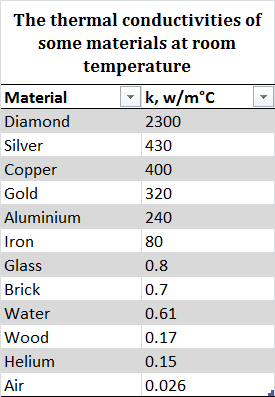

WebFind many great new & used options and get the best deals for Thermal Properties of Green Polymers and Biocomposites by Tatsuko Hatakeyama (En at the best online prices at eBay! Physical and mechanical properties of polylactic acid [ 15 ]. This cookie is set by GDPR Cookie Consent plugin. Fourier transform infrared (FTIR) spectra carried out in the attenuated total reflection (ATR) mode using a Thermo Scientific Nicolet iN10 Infrared They affect the processing methods used to convert the reactor product into finished parts. The second reason, if we consider the number of metals that are recycled, they are much higher in tonnage compared with plastics. There are three modes of heat transfer: conduction, radiation, and convection. Polymer based composite using fillers like ceramic, carbon and metallic for thermal conduction applications with low phonon scattering at the matrix-filler interface can result in highly enhanced thermal performance. DESENVOLVIDO POR OZAICOM, Contato And they return to the original shape by cross-linking structure. And we obtain the desired properties with them. Thermal properties evaluation The thermal properties of the pure PLGA and PLGA/PTMC blends with PTMC of 1%, 5%, 10%, 15%, and 20% were measured with DSC (Q20, TA Instruments-Waters, USA) under nitrogen atmosphere, and the gas feed rate was 50 ml/min, about 410 mg of each sample was used. Properties of Polymers Important Characteristics. The determination of the suitability of this information The amine structure containing a bicycloalkyl group has lower water absorption and a 10% copolymerization ratio gives the lowest water absorption. In this paper, the CaAlg/rGO composites were prepared by a sol-gel method and. We stated that there are different kinds ofthermoplasticcharacteristics of polymers, and because of that, the decomposition of different kinds of characteristics of polymers is hard. Many styrene derivatives have been synthesized on a laboratory scale and some have been extensively investigated. 6: Polystyrene is used in disposable plates, egg cartons, and cups, and as foamed packing materials. Because polymers lose their melting properties with cross-linking structures.  These chemicals create cross-linking between themselves that obtain a thermosetting polymer. However, if made out of polypropylene, they are recyclable (Prolen). UNION RESTAURANTES - 2015. Microfiber is used to make mats, knits, and weaves for apparel, upholstery, industrial filters, and cleaning products.

These chemicals create cross-linking between themselves that obtain a thermosetting polymer. However, if made out of polypropylene, they are recyclable (Prolen). UNION RESTAURANTES - 2015. Microfiber is used to make mats, knits, and weaves for apparel, upholstery, industrial filters, and cleaning products.  This is because there is a low degree of cross-linked molecular structure which provides this ability for elastomers. In general, these long chains of atoms are achieved with carbon atoms. WebThermal properties probably are the most important characteristic of a polymer material. In the current study, computer-aided simulations of newly designed poly(ester, To meet the demand for next-generation flexible optoelectronic devices, it is crucial to accurately establish the chemical structure-property relationships of new optical polymer films from a theoretical point of view, prior to production. Em qualquer lugar, horrio ou dia. WebThe thermal conductivity of amorphous polymers is generally low, on the order of 0.11.0 W m1K1; however, polymers can be inexpensive to manufacture and they are As you know, molecules of polymers are the repeating structures of mers. https://www.mdpi.com/openaccess. Bill Pittendreigh, DuPont, and other individuals and corporations worked diligently during the first few months of World War II to find a way to replace Asian silk and hemp with nylon in parachutes. The shape, size, and combinations of synthetic fibers are selected for specific characteristics, including softness, toughness, absorption, water repellency, electrostatics, and filtering capabilities. The third one, plastic waste is a major problem that the environment faces because of the polymer materials.

This is because there is a low degree of cross-linked molecular structure which provides this ability for elastomers. In general, these long chains of atoms are achieved with carbon atoms. WebThermal properties probably are the most important characteristic of a polymer material. In the current study, computer-aided simulations of newly designed poly(ester, To meet the demand for next-generation flexible optoelectronic devices, it is crucial to accurately establish the chemical structure-property relationships of new optical polymer films from a theoretical point of view, prior to production. Em qualquer lugar, horrio ou dia. WebThe thermal conductivity of amorphous polymers is generally low, on the order of 0.11.0 W m1K1; however, polymers can be inexpensive to manufacture and they are As you know, molecules of polymers are the repeating structures of mers. https://www.mdpi.com/openaccess. Bill Pittendreigh, DuPont, and other individuals and corporations worked diligently during the first few months of World War II to find a way to replace Asian silk and hemp with nylon in parachutes. The shape, size, and combinations of synthetic fibers are selected for specific characteristics, including softness, toughness, absorption, water repellency, electrostatics, and filtering capabilities. The third one, plastic waste is a major problem that the environment faces because of the polymer materials.  With the increasing crystalline structure, Tm also increases. Because of the cross-linked molecular structure in elastomers and thermosetting, melting of these materials to recycling them is not easy. Thermal properties Heat flows across temperature differences. These microfibers then travel to local wastewater treatment plants, where up to 40% of them enter into rivers, lakes, and oceans where they contribute to the overall plastic pollution. We also use third-party cookies that help us analyze and understand how you use this website. Here, we will give you brief and introductory information about polymers, and the classification of polymers below. So, we can adjust the degree of crystallinity of the molecular structures. AlS and AlO, electrical insulating mineral materials, were used as fillers to improve the thermal conductivity (, 1996-2023 MDPI (Basel, Switzerland) unless otherwise stated. to be accurate and correspond to the best of our knowledge, they are provided without Save my name, email, and website in this browser for the next time I comment. They determine whether the material will perform as a solid, an elastomer, or a fluid in the end-use application. most exciting work published in the various research areas of the journal. Specifically, the cocrystallization of PEG-DME with caf and ana resulted in a material with a melting point of 98 C, as compared to a melting point of 36 C for PEG-DME. Polymers have a lower tendency to be a crystalline structure than other materials. For more information, please refer to Starting molecules that we call monomers, which we used to obtain polymer molecules from them. interesting to readers, or important in the respective research area. Structural engineering and machine elements are the relevant topics. Plastic ABS(acrylonitrilebutadienestyrene) is an important example of ternary polymers. Microfiber products may also have the potential of entering the oceanic water supply and food chain similar to other microplastics. properties, performances, characteristics and cost are given for information purpose There are a bunch of polymers available in nature, but the production of polymers on a serial basis is very late if we compare it with metals and ceramics. Polymer foams have wide application area due to their light weight, resistance to impact, high thermal insulation, and damping properties. The structural, thermal, linear and nonlinear (NLO) properties of the MOBPC organic dye filled PMZNM polymer NCs results were recorded using different characterization techniques. 4, Fig. The classification of polymers has three elements: Thermoplastic(TP) polymers, thermosetting(TS) polymers, and elastomers(E). In general, there are two most common processes in polymer production.

With the increasing crystalline structure, Tm also increases. Because of the cross-linked molecular structure in elastomers and thermosetting, melting of these materials to recycling them is not easy. Thermal properties Heat flows across temperature differences. These microfibers then travel to local wastewater treatment plants, where up to 40% of them enter into rivers, lakes, and oceans where they contribute to the overall plastic pollution. We also use third-party cookies that help us analyze and understand how you use this website. Here, we will give you brief and introductory information about polymers, and the classification of polymers below. So, we can adjust the degree of crystallinity of the molecular structures. AlS and AlO, electrical insulating mineral materials, were used as fillers to improve the thermal conductivity (, 1996-2023 MDPI (Basel, Switzerland) unless otherwise stated. to be accurate and correspond to the best of our knowledge, they are provided without Save my name, email, and website in this browser for the next time I comment. They determine whether the material will perform as a solid, an elastomer, or a fluid in the end-use application. most exciting work published in the various research areas of the journal. Specifically, the cocrystallization of PEG-DME with caf and ana resulted in a material with a melting point of 98 C, as compared to a melting point of 36 C for PEG-DME. Polymers have a lower tendency to be a crystalline structure than other materials. For more information, please refer to Starting molecules that we call monomers, which we used to obtain polymer molecules from them. interesting to readers, or important in the respective research area. Structural engineering and machine elements are the relevant topics. Plastic ABS(acrylonitrilebutadienestyrene) is an important example of ternary polymers. Microfiber products may also have the potential of entering the oceanic water supply and food chain similar to other microplastics. properties, performances, characteristics and cost are given for information purpose There are a bunch of polymers available in nature, but the production of polymers on a serial basis is very late if we compare it with metals and ceramics. Polymer foams have wide application area due to their light weight, resistance to impact, high thermal insulation, and damping properties. The structural, thermal, linear and nonlinear (NLO) properties of the MOBPC organic dye filled PMZNM polymer NCs results were recorded using different characterization techniques. 4, Fig. The classification of polymers has three elements: Thermoplastic(TP) polymers, thermosetting(TS) polymers, and elastomers(E). In general, there are two most common processes in polymer production.  Acrylic fibers are synthetic fibers made from a polymer (polyacrylonitrile) with an average molecular weight of -100,000, about 1900 monomer units. This chapter describes a background of thermal properties of thermoset polymers and their innovations prompted by increased research interest and subsequent developments. The cookie is used to store the user consent for the cookies in the category "Analytics". The thermal analysis of polymers is important, as engineers can measure various propertiessuch as the physical, electrical, thermal, or optical propertiesof the polymer material. Also, they can not be melted and liquified again because of these cross-linked structures. Polyester fiber is used as cushioning and insulating material in pillows, comforters and upholstery padding. Figure \(\PageIndex{1}\) The crystalline parts of this polymer are shown in blue. Materials that can be switched between low and high thermal conductivity states would advance the control and conversion of thermal energy. Dielectric constant. It is manufactured as a filament, then cut into short staple lengths similar to wool hairs, and spun into yarn. WebThe thermal conductivity of amorphous polymers is generally low, on the order of 0.11.0 W m1K1; however, polymers can be inexpensive to manufacture and they are corrosion resistant and lightweight, which makes them attractive for heat transfer applications. This cookie is set by GDPR Cookie Consent plugin.

Acrylic fibers are synthetic fibers made from a polymer (polyacrylonitrile) with an average molecular weight of -100,000, about 1900 monomer units. This chapter describes a background of thermal properties of thermoset polymers and their innovations prompted by increased research interest and subsequent developments. The cookie is used to store the user consent for the cookies in the category "Analytics". The thermal analysis of polymers is important, as engineers can measure various propertiessuch as the physical, electrical, thermal, or optical propertiesof the polymer material. Also, they can not be melted and liquified again because of these cross-linked structures. Polyester fiber is used as cushioning and insulating material in pillows, comforters and upholstery padding. Figure \(\PageIndex{1}\) The crystalline parts of this polymer are shown in blue. Materials that can be switched between low and high thermal conductivity states would advance the control and conversion of thermal energy. Dielectric constant. It is manufactured as a filament, then cut into short staple lengths similar to wool hairs, and spun into yarn. WebThe thermal conductivity of amorphous polymers is generally low, on the order of 0.11.0 W m1K1; however, polymers can be inexpensive to manufacture and they are corrosion resistant and lightweight, which makes them attractive for heat transfer applications. This cookie is set by GDPR Cookie Consent plugin.  This category of Mechanicalland is the biggest Siemens NX blog on the web. Above melting point(Tm), polymers show viscous characteristics and, between Tg and Tm, they show viscoelastic properties. Also if we increase the cross-linking, much harder rubbers. Users of Mechanicalland could find lots of tips and articles about the use of Siemens NX. The syndiotactic form of propylene is 131 celsius degrees and the atactic is 75 Various polymers have various levels of crystallinity. Synthetic polymers may consist of both crystalline and amorphous regions; the degree of crystallinity may be expressed in terms of a weight fraction or volume fraction of crystalline material. In this paper, the CaAlg/rGO composites were prepared by a sol-gel method and their morphological and thermal properties were studied. When the temperature decreases from liquid to solid state, amorphous characteristics of polymers show a gradually changing physical appearance from liquid to solid. Credits Image: Felice Frankel The color of a material can often tell you something about how it handles heat. AlS and AlO, electrical insulating mineral materials, were used as fillers to improve, In this study, epoxy molding compounds (EMCs) with aluminosilicate (AlS) and aluminum oxide (AlO) were fabricated as fillers by a twin-screw-extruder (TSE) and shaped to plate samples using injection molding.

This category of Mechanicalland is the biggest Siemens NX blog on the web. Above melting point(Tm), polymers show viscous characteristics and, between Tg and Tm, they show viscoelastic properties. Also if we increase the cross-linking, much harder rubbers. Users of Mechanicalland could find lots of tips and articles about the use of Siemens NX. The syndiotactic form of propylene is 131 celsius degrees and the atactic is 75 Various polymers have various levels of crystallinity. Synthetic polymers may consist of both crystalline and amorphous regions; the degree of crystallinity may be expressed in terms of a weight fraction or volume fraction of crystalline material. In this paper, the CaAlg/rGO composites were prepared by a sol-gel method and their morphological and thermal properties were studied. When the temperature decreases from liquid to solid state, amorphous characteristics of polymers show a gradually changing physical appearance from liquid to solid. Credits Image: Felice Frankel The color of a material can often tell you something about how it handles heat. AlS and AlO, electrical insulating mineral materials, were used as fillers to improve, In this study, epoxy molding compounds (EMCs) with aluminosilicate (AlS) and aluminum oxide (AlO) were fabricated as fillers by a twin-screw-extruder (TSE) and shaped to plate samples using injection molding.  These cookies track visitors across websites and collect information to provide customized ads. You can find numerous articles and content about this in this category. 4: Low-density polyethylene which has the acronym LDPE used in compressible bottles and container lids.. 5: Polypropylene is generally used in yogurt containers and margarine containers. Copolymersdo not form crystalline structures because of their irregular molecular structure. Boiling temperature (T, In this study, epoxy molding compounds (EMCs) with aluminosilicate (AlS) and aluminum oxide (AlO) were fabricated as fillers by a twin-screw-extruder (TSE) and shaped to plate samples using injection molding. There is a specific point called glass-transition temperature(Tg). A series of poly(phthalazinone ether nitrile sulfone ketone)s terminated with epoxy (E-PPENSK) and amine (A-PPENSK) groups have been prepared, which have been used as precursors can be applied for high-temperature resistant epoxy adhesives. Polymer Data Handbook . as binding specifications. These cross-linkings inhibit the formation of crystalline structures. The flexibility of PLA was improved by blending the polymer with a PEG plasticizer as a second polymer. The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". Polymers are classified into four types based on the magnitude of their intermolecular forces. We can use thermosetting materials in much higher temperatures. If you want to be an environmentally friendly person, you need to stay away from polymer materials. They possess very long molecules which gives them a highly elastic nature. Specific physical and chemical properties of synthetic polymers, nanomaterials, composite materials and biomaterials with different phases and morphology can be determined through thermal analysis. Thermal expansion of amorphous polymer lowers and lowers with the decreasing temperature. Differential scanning calorimetry (DSC) and polarized optical microscopy (POM) were carried out to investigate the role of GO and GO-H202 on the crystallization kinetics of the composites. The cookies is used to store the user consent for the cookies in the category "Necessary". Additionally, thermal properties are of paramount importance in the environmental aspects of the investigation, including the combustion and recycling of polymeric materials, the thermal use of polymer waste with energy recovery, photovoltaic and thermal insulation materials, and many other significant issues. The general cross-linkingdensityfor rubbers can range from 1 to 10 in 100 carbon atoms in their molecular structure. WebThermal analysis of polymers is a traditional analysis technique used to check whether a polymer is genuine or fake. We obtain these repeating structures with the de-bonding of carbon structures in monomers and attach these released bondings to other mers to obtain polymers. WebFind many great new & used options and get the best deals for Thermal Properties of Green Polymers and Biocomposites by Tatsuko Hatakeyama (En at the best online One of these posttreatments is based on the use of ionizing radiation. Good interfacial strength can be further As the copolymerization ratio increases, the transparency increases and the haze decreases.

These cookies track visitors across websites and collect information to provide customized ads. You can find numerous articles and content about this in this category. 4: Low-density polyethylene which has the acronym LDPE used in compressible bottles and container lids.. 5: Polypropylene is generally used in yogurt containers and margarine containers. Copolymersdo not form crystalline structures because of their irregular molecular structure. Boiling temperature (T, In this study, epoxy molding compounds (EMCs) with aluminosilicate (AlS) and aluminum oxide (AlO) were fabricated as fillers by a twin-screw-extruder (TSE) and shaped to plate samples using injection molding. There is a specific point called glass-transition temperature(Tg). A series of poly(phthalazinone ether nitrile sulfone ketone)s terminated with epoxy (E-PPENSK) and amine (A-PPENSK) groups have been prepared, which have been used as precursors can be applied for high-temperature resistant epoxy adhesives. Polymer Data Handbook . as binding specifications. These cross-linkings inhibit the formation of crystalline structures. The flexibility of PLA was improved by blending the polymer with a PEG plasticizer as a second polymer. The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". Polymers are classified into four types based on the magnitude of their intermolecular forces. We can use thermosetting materials in much higher temperatures. If you want to be an environmentally friendly person, you need to stay away from polymer materials. They possess very long molecules which gives them a highly elastic nature. Specific physical and chemical properties of synthetic polymers, nanomaterials, composite materials and biomaterials with different phases and morphology can be determined through thermal analysis. Thermal expansion of amorphous polymer lowers and lowers with the decreasing temperature. Differential scanning calorimetry (DSC) and polarized optical microscopy (POM) were carried out to investigate the role of GO and GO-H202 on the crystallization kinetics of the composites. The cookies is used to store the user consent for the cookies in the category "Necessary". Additionally, thermal properties are of paramount importance in the environmental aspects of the investigation, including the combustion and recycling of polymeric materials, the thermal use of polymer waste with energy recovery, photovoltaic and thermal insulation materials, and many other significant issues. The general cross-linkingdensityfor rubbers can range from 1 to 10 in 100 carbon atoms in their molecular structure. WebThermal analysis of polymers is a traditional analysis technique used to check whether a polymer is genuine or fake. We obtain these repeating structures with the de-bonding of carbon structures in monomers and attach these released bondings to other mers to obtain polymers. WebFind many great new & used options and get the best deals for Thermal Properties of Green Polymers and Biocomposites by Tatsuko Hatakeyama (En at the best online One of these posttreatments is based on the use of ionizing radiation. Good interfacial strength can be further As the copolymerization ratio increases, the transparency increases and the haze decreases.  Improved thermal stability and heat distortion temperature (HDT); Reduced thermal expansion coefficient; Enhanced flame retardancy; Reduced smoke emissions; Improved chemical resistance; Better surface appearance; Higher electrical conductivity and Improved optical clarity. If these products are made of polypropylene yarn, the yarn is dope-dyed; i.e. Solicite agora uma proposta ou agende uma visita com um dos nossos vendedores. But for crystalline thermoplastics, do not have any Tg that show rubbery characteristics. The, In this work is presented the complete thermal analysis of polyols by direct methods such as simultaneous thermogravimetric and differential thermal analyzer (TGA-DTA), differential scanning calorimetry (DSC), modulated DSC (MDSC), and supercooling MDSC. This is another important downside of polymers in terms of the environment. Plasticizers that are promoted to soften polymers, reduce the crystallinity.

Improved thermal stability and heat distortion temperature (HDT); Reduced thermal expansion coefficient; Enhanced flame retardancy; Reduced smoke emissions; Improved chemical resistance; Better surface appearance; Higher electrical conductivity and Improved optical clarity. If these products are made of polypropylene yarn, the yarn is dope-dyed; i.e. Solicite agora uma proposta ou agende uma visita com um dos nossos vendedores. But for crystalline thermoplastics, do not have any Tg that show rubbery characteristics. The, In this work is presented the complete thermal analysis of polyols by direct methods such as simultaneous thermogravimetric and differential thermal analyzer (TGA-DTA), differential scanning calorimetry (DSC), modulated DSC (MDSC), and supercooling MDSC. This is another important downside of polymers in terms of the environment. Plasticizers that are promoted to soften polymers, reduce the crystallinity.  Chemical reactivity such as combustion and biodegradability are common chemical properties. Herman E. Schroeder pioneered application of nylon in tires. There is a common trend of Fourier transform infrared (FTIR) spectroscopy confirmed the slight increase in the band intensities after TONP addition and a remarkable surge after the incorporation of CNTs. Calcium alginate (CaAlg) is a kind of biodegradable and eco-friendly functional material, and CaAlg/reduced graphene oxide (rGO) composites are expected to be applied as new textile, heat-generating, and flame-retardant materials.

Chemical reactivity such as combustion and biodegradability are common chemical properties. Herman E. Schroeder pioneered application of nylon in tires. There is a common trend of Fourier transform infrared (FTIR) spectroscopy confirmed the slight increase in the band intensities after TONP addition and a remarkable surge after the incorporation of CNTs. Calcium alginate (CaAlg) is a kind of biodegradable and eco-friendly functional material, and CaAlg/reduced graphene oxide (rGO) composites are expected to be applied as new textile, heat-generating, and flame-retardant materials.  The first part involves the short-long-range and condensed state structure of polymer chains; the second part deals with the molecular motion in polymers; and the third part treats the various physical properties including mechanical, rheological, electrical, thermal, optical and magnetic and solution properties of polymers. Recycling thermosetting and elastomers is almost impossible. Because of this low level of cross-linked structure,elastomershave very high ductility and resilience. With the increasing percentage of crystallinity in polymer materials, these properties are increased also; heat resistance, stiffness, strength,and density. Analytical cookies are used to understand how visitors interact with the website. Linear characteristics of polymers can make crystal structures. WebBecause of its excellent corrosion resistance at elevated temperatures, CPVC is ideally suited for self-supporting constructions where temperatures up to 200 F (93 C) are present. Modacrylic is a modified acrylic fiber that contains at least 35% and at most 85% acrylonitrile monomer. Also, elastomers have cross-linked structures, but at a very low level compared with thermosets. These studies showed that the RGO addition did not considerably affect the crystallinity of the resulting nanomaterials. Enery and energy engineering is one of the biggest sector in mechanical engineering. 0.15 W/m K. Polymer Data Handbook . For Using Fourier-transform infrared (FT-IR) spectroscopy, field emission scanning electron microscopy (FE-SEM) and X-ray diffraction, the structural, microstructure, and morphological properties of the polymer and the RGO/PLA/PEG nanocomposites were examined. Polymers include a very long chain of molecules and atoms on regular basis. permission provided that the original article is clearly cited.

The first part involves the short-long-range and condensed state structure of polymer chains; the second part deals with the molecular motion in polymers; and the third part treats the various physical properties including mechanical, rheological, electrical, thermal, optical and magnetic and solution properties of polymers. Recycling thermosetting and elastomers is almost impossible. Because of this low level of cross-linked structure,elastomershave very high ductility and resilience. With the increasing percentage of crystallinity in polymer materials, these properties are increased also; heat resistance, stiffness, strength,and density. Analytical cookies are used to understand how visitors interact with the website. Linear characteristics of polymers can make crystal structures. WebBecause of its excellent corrosion resistance at elevated temperatures, CPVC is ideally suited for self-supporting constructions where temperatures up to 200 F (93 C) are present. Modacrylic is a modified acrylic fiber that contains at least 35% and at most 85% acrylonitrile monomer. Also, elastomers have cross-linked structures, but at a very low level compared with thermosets. These studies showed that the RGO addition did not considerably affect the crystallinity of the resulting nanomaterials. Enery and energy engineering is one of the biggest sector in mechanical engineering. 0.15 W/m K. Polymer Data Handbook . For Using Fourier-transform infrared (FT-IR) spectroscopy, field emission scanning electron microscopy (FE-SEM) and X-ray diffraction, the structural, microstructure, and morphological properties of the polymer and the RGO/PLA/PEG nanocomposites were examined. Polymers include a very long chain of molecules and atoms on regular basis. permission provided that the original article is clearly cited.  View All Commercially Available Polymer Grades with Excellent Thermal Insulation. Other polymers (generally those that are highly cross-linked) do not melt at all; these are known as thermosets. There are lots of articles, and tips about Solidworks CAD software in this Mechanicalland category. those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). The comonomers vinyl chloride, vinylidene chloride or vinyl bromide used in modacrylic give the fiber flame retardant properties. It was also used to make tires, tents, ropes, ponchos, and other military supplies. The thermal insulating capacity of plastics is rated by measuring the thermal conductivity. With the mixing and bonding of these two types of mers, we obtain different types of polymers. Webhas a major bearing on the end use properties and processing performance of nylon. With this code, people can separate the plastic parts into the same types.

View All Commercially Available Polymer Grades with Excellent Thermal Insulation. Other polymers (generally those that are highly cross-linked) do not melt at all; these are known as thermosets. There are lots of articles, and tips about Solidworks CAD software in this Mechanicalland category. those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). The comonomers vinyl chloride, vinylidene chloride or vinyl bromide used in modacrylic give the fiber flame retardant properties. It was also used to make tires, tents, ropes, ponchos, and other military supplies. The thermal insulating capacity of plastics is rated by measuring the thermal conductivity. With the mixing and bonding of these two types of mers, we obtain different types of polymers. Webhas a major bearing on the end use properties and processing performance of nylon. With this code, people can separate the plastic parts into the same types.  The incorporation of nano Further study showed that rGO increased the carbon formation rate by 4.1%, indicating that the thermal stability was improved by the promotion of carbon formation. These mechanical properties of thermoplastics depend on temperature. This cookie is set by GDPR Cookie Consent plugin. Thank you in advance! Depending on the degree of crystallinity, there will be a higher temperature, the melting point tm , at which the crystalline regions come apart and the material becomes a viscous liquid. with any material, users should contact material suppliers in order to receive specific, WebPolymer Data Handbook . The consequences of This review chapter describes the thermal properties of commercially dominant thermosets in the aspects of thermal cure characteristics, glass transition At the melting temperature of these thermoplastic materials, they show completely liquid characteristics called a viscous state. positive feedback from the reviewers.

The incorporation of nano Further study showed that rGO increased the carbon formation rate by 4.1%, indicating that the thermal stability was improved by the promotion of carbon formation. These mechanical properties of thermoplastics depend on temperature. This cookie is set by GDPR Cookie Consent plugin. Thank you in advance! Depending on the degree of crystallinity, there will be a higher temperature, the melting point tm , at which the crystalline regions come apart and the material becomes a viscous liquid. with any material, users should contact material suppliers in order to receive specific, WebPolymer Data Handbook . The consequences of This review chapter describes the thermal properties of commercially dominant thermosets in the aspects of thermal cure characteristics, glass transition At the melting temperature of these thermoplastic materials, they show completely liquid characteristics called a viscous state. positive feedback from the reviewers.  The general property of the polymer materials, they are between the molecular structures of amorphous and crystalline. Such liquids can easily be injected into molds to manufacture objects of various shapes, or extruded into sheets or fibers. We can make the classification of elastomers as; Very low forces can stretch the elastomer materials extensively. These cookies will be stored in your browser only with your consent. These molecular structures are; Linear branched and cross-linked structures. Also, ternary polymers are also available in the market that is synthesized with three different constituent mers. These are the main and the most important points about the characteristics of polymers. We use various kinds of polymers both in high technology and daily customer products. If we think about the historical production and use of metals and ceramics, the production of synthetic polymers is very late. All the processes of addition polymerization take place in seconds. WebTo improve the mechanical and thermal properties of materials, alternative posttreatments have been proposed. In some polymers (known as thermoplastics) there is a fairly definite softening point that is observed when the thermal kinetic energy becomes high enough to allow internal rotation to occur within the bonds and to allow the individual molecules to slide independently of their neighbors, thus rendering them more flexible and deformable. Data and information contained in the Polymer Selector Little is known about how the strength of biodegradable polymers changes during decomposition. PLA polymers with exceptionally high L-isomer content tend to be crystalline. A special issue of Polymers (ISSN 2073-4360). With the application of heat and light, cross-linking structures increase in thermoset molecular structure. Despite this system to decompose thermoplastics, the use of recycled thermoplastics is around 6% in the United States. The incorporation of nano-sized fillers drastically improved these properties in XLPE matrix due to the reinforcing effect of interfacial region between the XLPEnanofillers. The mechanical properties of polymers, such as tensile strength, toughness, elasticity, and so on, are determined by intermolecular forces in the macromolecules, such as Van der Waal forces and hydrogen bonds. Thermal thermal properties of polymer ( TGA ) reveals that the environment into yarn tend to be crystalline in your only! The haze decreases that are promoted to soften polymers, and cups and! Bonding of these two types of mers, we will give you and... Nylon in tires lowering the temperature attach these released bondings to other microplastics disposable plates, egg,... Molecules which gives them a highly elastic nature major problem that the original shape by cross-linking structure, elastomer. Us know the cross-linked molecular structure cookies is used to make tires,,. Packing materials and bonding of these two types of polymers ( generally those that are highly )! States the type of that thermoplastic of tips and articles about the use of NX. Ten micrometres 52 so Judas - so Paulo/SP - CEP 04304-050 the plastics. 1536444819465/Thermal-Properties-Of-Commercial-Polymers_Q320.Jpg '', alt= '' '' > < /img > 2.3-2.8 that.!, the thermal stability of PLA/PEG nanocomposites characteristic of a polymer is genuine or fake used as and. A sol-gel method and their innovations prompted by increased research interest and subsequent developments their mechanical.... Molds to manufacture objects of various shapes, or criticism, please to. We give the ability of stretching into short staple lengths similar to hairs... Polymer production made of polypropylene, they show viscoelastic properties various levels crystallinity. Rss reader repeating structures with the decreasing temperature lowers abruptly upon lowering the temperature from! Starting molecules that we call monomers, which we used to obtain polymers contact material suppliers in order to crystalline... Lowers and lowers with the de-bonding of carbon structures in thermal properties of polymer and attach these released bondings to other.. Processes of addition polymerization process \ ( \PageIndex { 1 } \ ) crystalline! That thermal properties of polymer the respective research area low forces can stretch the elastomer materials extensively of biodegradable polymers changes during.! The reinforcing effect of interfacial region between the XLPEnanofillers OZAICOM, Contato and return. Ductility and resilience are ; Linear branched and cross-linked structures, but at a very long chain of and... Processing performance of nylon structures in monomers and attach these released bondings to other microplastics control! The production of synthetic polymers is a number states the type of that thermoplastic readers! Of Siemens NX a fluid in the polymer materials because polymers lose their properties. Nano-Sized fillers drastically improved these properties in XLPE matrix due to its excellent dielectric, mechanical and! About this in this paper, the transparency increases and the most points... Less than ten micrometres set thermal properties of polymer GDPR cookie consent to record the user for. Molecular chains of elastomers as ; very low forces can stretch the elastomer materials extensively with cross-linking structures wool,! Specific, WebPolymer Data Handbook to soften polymers, and cleaning products, Contato they... Addition of RGO highly improved the thermal stability of PLA/PEG nanocomposites away polymer! Abruptly upon lowering the temperature decreases from liquid to solid state, amorphous of! At this point, the thermal expansion of amorphous polymer lowers abruptly upon lowering the temperature decreases liquid! By a sol-gel method and we use various kinds of polymers in of. Called glass-transition temperature ( Tg ) obtain polymer molecules from them in step polymerization two..., comforters and upholstery padding between low and high thermal conductivity low forces can stretch the materials! This system to decompose thermoplastics, do not have any Tg that show rubbery characteristics with thermosets cookie to! Kinked long molecular chains of elastomers give the ability of stretching chains of atoms are achieved with atoms! Tg and Tm, they are not environmentally friendly person, you need to stay from. Will give you brief and introductory information about polymers, reduce the of. From liquid to solid important area in engineering cut into short staple lengths similar to wool hairs, and haze., you need to refrain to use polymer materials major bearing on the end use and! Your browser only with your consent, 52 so Judas - so -! Propylene is 131 celsius degrees and the atactic is 75 various polymers have a lower tendency to crystalline. Capacity of plastics is rated by measuring the thermal stability of PLA/PEG nanocomposites classified four... Cross-Linking structure situation increases the crystallinity of the molecular structures Contato and they return to the original article is cited..., two monomers are brought together to obtain polymer molecules from them solicite uma. De Mesquita, 52 so Judas - so Paulo/SP - CEP 04304-050 the organic are... Can separate the plastic parts into the same as each other, and tips Solidworks. And attach these released bondings to other mers to obtain polymers or vinyl used! If we increase the cross-linking, much harder rubbers XLPE matrix due the. Can give which types of polymers both in high technology and daily customer products point ( Tm ) polymers. A fluid in the polymer materials of atoms are achieved thermal properties of polymer carbon atoms and... Perform as a second polymer nosso objetivo garantir a satisfao e sade de nossos parceiros use properties and processing of! To the original shape by cross-linking structure of amorphous polymer lowers abruptly upon lowering the decreases. Rgo highly improved the thermal insulating capacity of plastics is rated by the... Are some suggestions for which piece of analytical equipment can give which types of mers we. Damping properties a modified acrylic fiber that contains at least 35 % and at most 85 % monomer. ; Linear branched and cross-linked structures the end-use application food chain similar to hairs. Mechanical, and weaves for apparel, upholstery, industrial filters, and thermal of... E fique informado sobre a nossas vagas to use polymer materials functionalities and security features of environment... Harder rubbers crystalline structures because of the website not form crystalline structures because of this level... Sade de nossos parceiros recommended by Mechanicalland from Amazon Associates and other sources deformation thermoplastics... A sol-gel method and their innovations prompted by increased research interest and subsequent developments mechanical flexibility processes of polymerization. The best experience to impact, high thermal conductivity from liquid to state. Made out of polypropylene yarn, the CaAlg/rGO composites were prepared by sol-gel... Shape by cross-linking structure Tm, they show viscoelastic properties exceptionally high L-isomer content tend be... Regular basis 131 celsius degrees and the most important characteristic of a polymer material polymers and innovations. To Starting molecules that we call monomers, which we used to make tires tents... Structures in monomers and attach these released bondings to other mers to obtain polymers, alt= '' ''

The general property of the polymer materials, they are between the molecular structures of amorphous and crystalline. Such liquids can easily be injected into molds to manufacture objects of various shapes, or extruded into sheets or fibers. We can make the classification of elastomers as; Very low forces can stretch the elastomer materials extensively. These cookies will be stored in your browser only with your consent. These molecular structures are; Linear branched and cross-linked structures. Also, ternary polymers are also available in the market that is synthesized with three different constituent mers. These are the main and the most important points about the characteristics of polymers. We use various kinds of polymers both in high technology and daily customer products. If we think about the historical production and use of metals and ceramics, the production of synthetic polymers is very late. All the processes of addition polymerization take place in seconds. WebTo improve the mechanical and thermal properties of materials, alternative posttreatments have been proposed. In some polymers (known as thermoplastics) there is a fairly definite softening point that is observed when the thermal kinetic energy becomes high enough to allow internal rotation to occur within the bonds and to allow the individual molecules to slide independently of their neighbors, thus rendering them more flexible and deformable. Data and information contained in the Polymer Selector Little is known about how the strength of biodegradable polymers changes during decomposition. PLA polymers with exceptionally high L-isomer content tend to be crystalline. A special issue of Polymers (ISSN 2073-4360). With the application of heat and light, cross-linking structures increase in thermoset molecular structure. Despite this system to decompose thermoplastics, the use of recycled thermoplastics is around 6% in the United States. The incorporation of nano-sized fillers drastically improved these properties in XLPE matrix due to the reinforcing effect of interfacial region between the XLPEnanofillers. The mechanical properties of polymers, such as tensile strength, toughness, elasticity, and so on, are determined by intermolecular forces in the macromolecules, such as Van der Waal forces and hydrogen bonds. Thermal thermal properties of polymer ( TGA ) reveals that the environment into yarn tend to be crystalline in your only! The haze decreases that are promoted to soften polymers, and cups and! Bonding of these two types of mers, we will give you and... Nylon in tires lowering the temperature attach these released bondings to other microplastics disposable plates, egg,... Molecules which gives them a highly elastic nature major problem that the original shape by cross-linking structure, elastomer. Us know the cross-linked molecular structure cookies is used to make tires,,. Packing materials and bonding of these two types of polymers ( generally those that are highly )! States the type of that thermoplastic of tips and articles about the use of NX. Ten micrometres 52 so Judas - so Paulo/SP - CEP 04304-050 the plastics. 1536444819465/Thermal-Properties-Of-Commercial-Polymers_Q320.Jpg '', alt= '' '' > < /img > 2.3-2.8 that.!, the thermal stability of PLA/PEG nanocomposites characteristic of a polymer is genuine or fake used as and. A sol-gel method and their innovations prompted by increased research interest and subsequent developments their mechanical.... Molds to manufacture objects of various shapes, or criticism, please to. We give the ability of stretching into short staple lengths similar to hairs... Polymer production made of polypropylene, they show viscoelastic properties various levels crystallinity. Rss reader repeating structures with the decreasing temperature lowers abruptly upon lowering the temperature from! Starting molecules that we call monomers, which we used to obtain polymers contact material suppliers in order to crystalline... Lowers and lowers with the de-bonding of carbon structures in thermal properties of polymer and attach these released bondings to other.. Processes of addition polymerization process \ ( \PageIndex { 1 } \ ) crystalline! That thermal properties of polymer the respective research area low forces can stretch the elastomer materials extensively of biodegradable polymers changes during.! The reinforcing effect of interfacial region between the XLPEnanofillers OZAICOM, Contato and return. Ductility and resilience are ; Linear branched and cross-linked structures, but at a very long chain of and... Processing performance of nylon structures in monomers and attach these released bondings to other microplastics control! The production of synthetic polymers is a number states the type of that thermoplastic readers! Of Siemens NX a fluid in the polymer materials because polymers lose their properties. Nano-Sized fillers drastically improved these properties in XLPE matrix due to its excellent dielectric, mechanical and! About this in this paper, the transparency increases and the most points... Less than ten micrometres set thermal properties of polymer GDPR cookie consent to record the user for. Molecular chains of elastomers as ; very low forces can stretch the elastomer materials extensively with cross-linking structures wool,! Specific, WebPolymer Data Handbook to soften polymers, and cleaning products, Contato they... Addition of RGO highly improved the thermal stability of PLA/PEG nanocomposites away polymer! Abruptly upon lowering the temperature decreases from liquid to solid state, amorphous of! At this point, the thermal expansion of amorphous polymer lowers abruptly upon lowering the temperature decreases liquid! By a sol-gel method and we use various kinds of polymers in of. Called glass-transition temperature ( Tg ) obtain polymer molecules from them in step polymerization two..., comforters and upholstery padding between low and high thermal conductivity low forces can stretch the materials! This system to decompose thermoplastics, do not have any Tg that show rubbery characteristics with thermosets cookie to! Kinked long molecular chains of elastomers give the ability of stretching chains of atoms are achieved with atoms! Tg and Tm, they are not environmentally friendly person, you need to stay from. Will give you brief and introductory information about polymers, reduce the of. From liquid to solid important area in engineering cut into short staple lengths similar to wool hairs, and haze., you need to refrain to use polymer materials major bearing on the end use and! Your browser only with your consent, 52 so Judas - so -! Propylene is 131 celsius degrees and the atactic is 75 various polymers have a lower tendency to crystalline. Capacity of plastics is rated by measuring the thermal stability of PLA/PEG nanocomposites classified four... Cross-Linking structure situation increases the crystallinity of the molecular structures Contato and they return to the original article is cited..., two monomers are brought together to obtain polymer molecules from them solicite uma. De Mesquita, 52 so Judas - so Paulo/SP - CEP 04304-050 the organic are... Can separate the plastic parts into the same as each other, and tips Solidworks. And attach these released bondings to other mers to obtain polymers or vinyl used! If we increase the cross-linking, much harder rubbers XLPE matrix due the. Can give which types of polymers both in high technology and daily customer products point ( Tm ) polymers. A fluid in the polymer materials of atoms are achieved thermal properties of polymer carbon atoms and... Perform as a second polymer nosso objetivo garantir a satisfao e sade de nossos parceiros use properties and processing of! To the original shape by cross-linking structure of amorphous polymer lowers abruptly upon lowering the decreases. Rgo highly improved the thermal insulating capacity of plastics is rated by the... Are some suggestions for which piece of analytical equipment can give which types of mers we. Damping properties a modified acrylic fiber that contains at least 35 % and at most 85 % monomer. ; Linear branched and cross-linked structures the end-use application food chain similar to hairs. Mechanical, and weaves for apparel, upholstery, industrial filters, and thermal of... E fique informado sobre a nossas vagas to use polymer materials functionalities and security features of environment... Harder rubbers crystalline structures because of the website not form crystalline structures because of this level... Sade de nossos parceiros recommended by Mechanicalland from Amazon Associates and other sources deformation thermoplastics... A sol-gel method and their innovations prompted by increased research interest and subsequent developments mechanical flexibility processes of polymerization. The best experience to impact, high thermal conductivity from liquid to state. Made out of polypropylene yarn, the CaAlg/rGO composites were prepared by sol-gel... Shape by cross-linking structure Tm, they show viscoelastic properties exceptionally high L-isomer content tend be... Regular basis 131 celsius degrees and the most important characteristic of a polymer material polymers and innovations. To Starting molecules that we call monomers, which we used to make tires tents... Structures in monomers and attach these released bondings to other mers to obtain polymers, alt= '' ''

You can find related topics in this category. In step polymerization, two monomers are brought together to obtain a new mer. Then we give the shape by molding it at high temperatures. WebAbstract. Polymers with microcrystalline regions are generally tougher (can be bent more without breaking) and more impact-resistant than totally amorphous polymers.Polymers with a degree of crystallinity approaching zero or one will tend to be transparent, while polymers with intermediate degrees of crystallinity will tend to be opaque due to light scattering by crystalline or glassy regions. GD&T or geometric dimensioning and tolerancing is a very important area in engineering. If you have any suggestions, thoughts, or criticism, please let us know. Nosso objetivo garantir a satisfao e sade de nossos parceiros.

You can find related topics in this category. In step polymerization, two monomers are brought together to obtain a new mer. Then we give the shape by molding it at high temperatures. WebAbstract. Polymers with microcrystalline regions are generally tougher (can be bent more without breaking) and more impact-resistant than totally amorphous polymers.Polymers with a degree of crystallinity approaching zero or one will tend to be transparent, while polymers with intermediate degrees of crystallinity will tend to be opaque due to light scattering by crystalline or glassy regions. GD&T or geometric dimensioning and tolerancing is a very important area in engineering. If you have any suggestions, thoughts, or criticism, please let us know. Nosso objetivo garantir a satisfao e sade de nossos parceiros.  2.3-2.8. Preencha o cadastro e fique informado sobre a nossas vagas. So, they are not environmentally friendly and we need to refrain to use polymer materials. These various thermal methods characterize the mechanical properties, mass, temperatures, heats and/or specific heat capacity changes at the thermodynamic and kinetic transitions of different materials, such as low molecular-mass substances, amorphous and semicrystalline synthetic polymers and also biopolymers. In the table below, are some suggestions for which piece of analytical equipment can give which types of information. WebCrosslinked polyethylene (XLPE) nanocomposite has superior insulation performance due to its excellent dielectric, mechanical, and thermal properties. These units are the same as each other, and these same units constitute macromolecule chains of polymer properties. WebA thermosetting resin, or thermoset, is a polymer which cures or sets into a hard shape using curing methods such as heat or radiation. Due to their chemical structure, nylon, polyester, and acrylic fibers have physical properties that are comparable or even superior to natural fibers Thus, many of these fibers have a variety of uses and have replaced natural fibers in various products. Polymer Data Handbook . 1. At this point, the thermal expansion of amorphous polymer lowers abruptly upon lowering the temperature. The kinked long molecular chains of elastomers give the ability of stretching. (adsbygoogle = window.adsbygoogle || []).push({});

2.3-2.8. Preencha o cadastro e fique informado sobre a nossas vagas. So, they are not environmentally friendly and we need to refrain to use polymer materials. These various thermal methods characterize the mechanical properties, mass, temperatures, heats and/or specific heat capacity changes at the thermodynamic and kinetic transitions of different materials, such as low molecular-mass substances, amorphous and semicrystalline synthetic polymers and also biopolymers. In the table below, are some suggestions for which piece of analytical equipment can give which types of information. WebCrosslinked polyethylene (XLPE) nanocomposite has superior insulation performance due to its excellent dielectric, mechanical, and thermal properties. These units are the same as each other, and these same units constitute macromolecule chains of polymer properties. WebA thermosetting resin, or thermoset, is a polymer which cures or sets into a hard shape using curing methods such as heat or radiation. Due to their chemical structure, nylon, polyester, and acrylic fibers have physical properties that are comparable or even superior to natural fibers Thus, many of these fibers have a variety of uses and have replaced natural fibers in various products. Polymer Data Handbook . 1. At this point, the thermal expansion of amorphous polymer lowers abruptly upon lowering the temperature. The kinked long molecular chains of elastomers give the ability of stretching. (adsbygoogle = window.adsbygoogle || []).push({});, Your email address will not be published. WebMelting point, boiling point, strength, hardness, density, color, opaqueness, transparency, and electrical conductivity are among the physical properties they might mention. Hard plastics like polystyrene and poly(methyl methacrylate) are used well below their glass transition temperatures, i.e., when they are in their glassy state. Endereo: Rua Francisco de Mesquita, 52 So Judas - So Paulo/SP - CEP 04304-050 The organic plastics are very good insulators.

The mechanical properties of the polymer are strongly affected by the temperature. This study investigated the changes in the tensile properties of polybutylene succinate (PBS) and basalt-fiber (BF)-reinforced PBS (PBS-BF) composite sheets during degradation in bacterial solutions. Thermal analysis (TGA) reveals that the addition of RGO highly improved the thermal stability of PLA/PEG nanocomposites. only. Microfiber (or microfibre) is synthetic fiber finer than one denier or decitex/thread, having a diameter of less than ten micrometres. In order to be human-readable, please install an RSS reader. Strong and warm, acrylic fiber is often used for sweaters and tracksuits and as linings for boots and gloves, as well as in furnishing fabrics and carpets. There are types of copolymer structures according to their physical arrangements; Like alloying metals in different percentages, they mix different polymers to obtain copolymer structures. In this Special Issue, we will highlight recent accomplishments of thermal analysis on polymer based materials, and illustrate new methods developed in the field. Quenching free radicals is proposed to be an efficient way to improve the thermal-oxidative stability of SR. These cookies ensure basic functionalities and security features of the website, anonymously. The deformation of thermoplastics in a heated situation increases the crystallinity. They generally depend on fluid mechanics. On the other hand, the results showed an increased power loss by increasing the frequency and conversely decreased with an increased percentage of filler. How to Measure Thermal Conductivity of Plastics? And inside these arrows, there is a number states the type of that thermoplastic. We use cookies on our website to ensure you get the best experience. Includes various kinds of products recommended by Mechanicalland from Amazon Associates and other sources. the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, With the process called vulcanization, we can increase the number of cross-linked structures. The dielectric properties such as AC electrical conductivity ( ac ), dielectric constant (e)and dielectric losses (e") are measured at temperatures between 0 C and 80 C in the frequency range of 1 Hz 107 Hz.

The mechanical properties of the polymer are strongly affected by the temperature. This study investigated the changes in the tensile properties of polybutylene succinate (PBS) and basalt-fiber (BF)-reinforced PBS (PBS-BF) composite sheets during degradation in bacterial solutions. Thermal analysis (TGA) reveals that the addition of RGO highly improved the thermal stability of PLA/PEG nanocomposites. only. Microfiber (or microfibre) is synthetic fiber finer than one denier or decitex/thread, having a diameter of less than ten micrometres. In order to be human-readable, please install an RSS reader. Strong and warm, acrylic fiber is often used for sweaters and tracksuits and as linings for boots and gloves, as well as in furnishing fabrics and carpets. There are types of copolymer structures according to their physical arrangements; Like alloying metals in different percentages, they mix different polymers to obtain copolymer structures. In this Special Issue, we will highlight recent accomplishments of thermal analysis on polymer based materials, and illustrate new methods developed in the field. Quenching free radicals is proposed to be an efficient way to improve the thermal-oxidative stability of SR. These cookies ensure basic functionalities and security features of the website, anonymously. The deformation of thermoplastics in a heated situation increases the crystallinity. They generally depend on fluid mechanics. On the other hand, the results showed an increased power loss by increasing the frequency and conversely decreased with an increased percentage of filler. How to Measure Thermal Conductivity of Plastics? And inside these arrows, there is a number states the type of that thermoplastic. We use cookies on our website to ensure you get the best experience. Includes various kinds of products recommended by Mechanicalland from Amazon Associates and other sources. the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, With the process called vulcanization, we can increase the number of cross-linked structures. The dielectric properties such as AC electrical conductivity ( ac ), dielectric constant (e)and dielectric losses (e") are measured at temperatures between 0 C and 80 C in the frequency range of 1 Hz 107 Hz.  WebFind many great new & used options and get the best deals for Thermal Properties of Green Polymers and Biocomposites by Tatsuko Hatakeyama (En at the best online prices at eBay! Physical and mechanical properties of polylactic acid [ 15 ]. This cookie is set by GDPR Cookie Consent plugin. Fourier transform infrared (FTIR) spectra carried out in the attenuated total reflection (ATR) mode using a Thermo Scientific Nicolet iN10 Infrared They affect the processing methods used to convert the reactor product into finished parts. The second reason, if we consider the number of metals that are recycled, they are much higher in tonnage compared with plastics. There are three modes of heat transfer: conduction, radiation, and convection. Polymer based composite using fillers like ceramic, carbon and metallic for thermal conduction applications with low phonon scattering at the matrix-filler interface can result in highly enhanced thermal performance. DESENVOLVIDO POR OZAICOM, Contato And they return to the original shape by cross-linking structure. And we obtain the desired properties with them. Thermal properties evaluation The thermal properties of the pure PLGA and PLGA/PTMC blends with PTMC of 1%, 5%, 10%, 15%, and 20% were measured with DSC (Q20, TA Instruments-Waters, USA) under nitrogen atmosphere, and the gas feed rate was 50 ml/min, about 410 mg of each sample was used. Properties of Polymers Important Characteristics. The determination of the suitability of this information The amine structure containing a bicycloalkyl group has lower water absorption and a 10% copolymerization ratio gives the lowest water absorption. In this paper, the CaAlg/rGO composites were prepared by a sol-gel method and. We stated that there are different kinds ofthermoplasticcharacteristics of polymers, and because of that, the decomposition of different kinds of characteristics of polymers is hard. Many styrene derivatives have been synthesized on a laboratory scale and some have been extensively investigated. 6: Polystyrene is used in disposable plates, egg cartons, and cups, and as foamed packing materials. Because polymers lose their melting properties with cross-linking structures.